Vietnam’s Rang Dong Showcases Smart Manufacturing, Innovations

Rang Dong, Vietnam’s leading manufacturer of LED and vacuum flask products, shared insights of its smart manufacturing at a forum as part of CMES Vietnam 2025, an international exhibition held in Hanoi on November 12-15. The event, organized by the Vietnam Automation Association and Huamo Group, brought together over 200 delegates, including government leaders, industry experts, manufacturers and technology developers from Vietnam and abroad.

Digital transformation and lean operations can empower enterprises to thrive in dynamic markets, said Rang Dong’s Deputy General Director Nguyen Hoang Keen in his presentation at the forum on innovation and artificial intelligence (AI) in machine tools.

Kien spoke of the importance of the Just-In-Time (JIT) principles, a strategy that aligns production closely with demand to minimize waste, and Zero Defect methodologies, which aim for flawless output through rigorous quality controls.

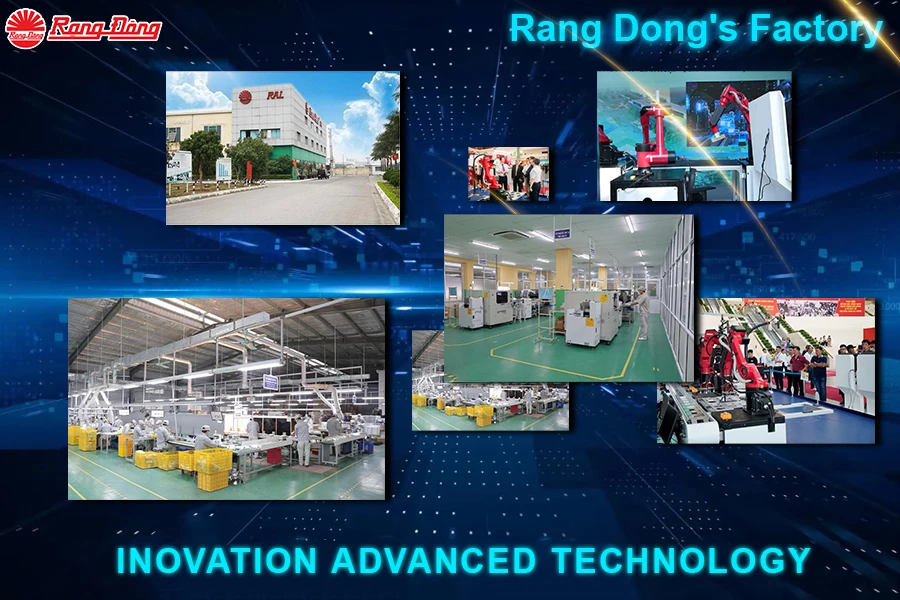

Rang Dong, fully known as Rang Dong Light Source and Vacuum Flask Joint Stock Company, employs JIT practices to streamline workflows, ensuring materials and components arrive precisely when needed, reducing inventory costs and storage demands, Keen said.

Coupled with Zero Defect, which leverage real-time monitoring and AI-driven inspections, Rang Dong has achieved high precision in LED lighting and smart home device production.

Central to these efforts is the use of Industrial Internet of Things (IIoT), or networks of connected devices that collect and share data across factory floors. IIoT sensors track equipment performance, detecting anomalies before they cause delays, while AI algorithms analyze output to maintain consistent quality.

For example, machine vision systems, or cameras paired with software to identify defects, ensure that every LED bulb meets strict standards, minimizing returns and enhancing customer trust. The technologies have helped Rang Dong cut production waste by 20 percent in recent years, Kien told the forum.

The company’s smart manufacturing framework also relies on a Digital Operations Center, which consolidates data from factory processes into a unified interface, allowing managers to monitor key metrics, such as energy consumption or throughput, and adjust operations instantly.

Such systems enable rapid responses to market shifts, such as sudden spikes in demand for energy-efficient products.

By embedding flexibility into its factories, Rang Dong sets a benchmark for others seeking to balance scale with responsiveness in Vietnam’s industrial parks.

Addressing Market Challenges

At the forum, Kien and industry experts discussed Demand-Driven Manufacturing, a model that prepares smart manufacturing to meet real-time market needs. The approach promotes agility, cost efficiency and environmental responsibility, which would help position Vietnam as a hub for intelligent and sustainable industry. Demand-driven manufacturing is a strategy that aligns production with customer preferences and market signals. Instead of relying on fixed schedules, the approach uses AI to forecast trends and optimize resource allocation.

Demand-driven manufacturing is a strategy that aligns production with customer preferences and market signals. Instead of relying on fixed schedules, the approach uses AI to forecast trends and optimize resource allocation.

For instance, Rang Dong’s systems analyze sales data to predict seasonal demands for smart lighting, adjusting output to avoid overstock while ensuring availability. This method not only lowers costs but also reduces energy use, contributing to greener operations, Kien said in a discussion.

AI plays a critical role in enabling this agility, from predictive maintenance that keeps machines running smoothly to supply chain optimizations that shorten delivery times. Kien said Rang Dong has been collaborating with local suppliers through shared digital platforms to ensure seamless coordination and faster market entry for new products.

These efforts align with Vietnam’s push for sustainable manufacturing, where efficiency gains translate into lower carbon footprints, which means each factory can remove hundreds of vehicles from roads annually.

Rang Dong’s engagement at the CMES Vietnam 2025 exhibition underscores its commitment to shaping a forward-looking industrial ecosystem. By championing flexible, AI-driven manufacturing, the company not only enhances its own operations but also inspires peers to embrace transformation.

Rang Dong’s participation also highlighted its leadership in adopting forward-thinking strategies that strengthens industrial competitiveness while addressing real-world challenges.

Should you have any questions or request a quotation of Rang Dong products, please send an email to: export@rangdong.com.vn.

Websites: en.rangdong.com.vn and vacuumflask.rangdong.com.vn.