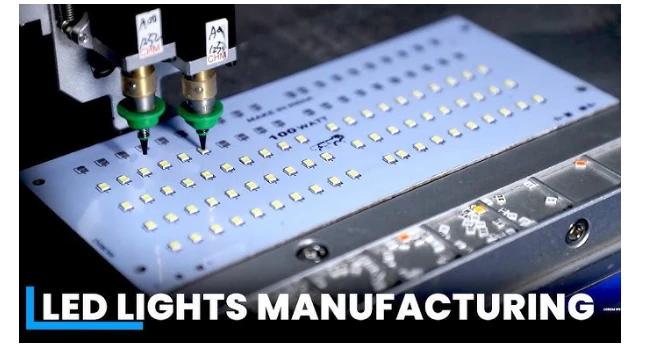

LED Bulb production line - A state-of-the-art production line of Rang Dong factory

Rang Dong is Vietnam's leading manufacturer of lighting products thanks to its strong capacity and long-standing reputation. LED bulbs make one of the company's most outstanding products. Currently, Rang Dong has five assembly lines for LED bulbs, making both type A and type T in the same process. We're looking closer at the LED bulb production line for making A60/A80 bulbs.

Operation of a semi-automatic assembly line for LED bulbs

First of all, once all the components are in place, workers print marks on light bases and place them on the conveyor belt leading to the automatic base feeding machine.

The bases will be transferred to the glue feeding stage by the conveyor belt. Workers inject LED modules into the glued bases.

Next is the LED module pressing stage. LED modules are placed tightly into the bases for the best thermal conductivity and heat dissipation.

Ask for LED modules, they are delivered from the automatic electronics section. Workers will split them and move to the AC cord attaching machine.

After that, the light covers with LED modules attached go to the AC cord shaping stage. Here AC cords are automatically reshaped and straightened before being moved to the LED bulb attaching stage.

Once the light covers are attached, LED bulb lights go through the first automatic lighting check. Those that light normally will have the extra cords cut and riveted.

The lights will be checked again, if any lights are not on, they will be automatically removed from the line and taken to the repair department.

The lights that pass the lighting check go to the riveting stage, where covers are fixed with bases.

The lights are picked up for the cover gluing stage. The cover feeding machine attaches the cover to the base and presses it so the two parts stick to each other more tightly.

The lights go through the testing stage, after which they go to the second automatic lighting check. Defect lights are automatically removed from the line.

After that, the lights will get barcode and production date printed, and stuck with a stamp.

Workers will check the appearance of the lights before putting them in the automatic packaging machine.

At the end of this packaging stage, a blower stands with a preset blowing level, if the lights are packed, they move on the line through the blower, while unpacked lights are blown out and moved to the start of the packaging stage for repackaging.

Should you have any questions, wish to share your ideas of lighting, or request a quotation, please send us an email: to export@rangdong.com.vn.

Our website: en.rangdong.com.vn.